Curvi HiFi continually strive to improve their designs – complacency is not an option for us, despite excellent reviews. Improvements to the Curvi-BMR are based on user partly on user feedback and the designer’s own observations.

These improvements were devised and implemented during the Covid-19 lockdown period. I would like to thank Trade CNC/Rapid 3D Solutions Ltd, Northwich (https://tradecnc.co.uk) (the beech plinth, hand router templates and composite components) and Sparta Ltd (http://www.sparta.co.uk), Burnley (bespoke inserts, BMR drive unit chassis reinforcement and floor coupling system), for delivering their excellent work during these challenging times. The cabinets were made pre-lockdown by Simon McLay of McLay Furniture (https://www.mclayfurniture.com). All wood surfaces have been hand finished using Littlefair’s wood finishing products (https://www.littlefairs.shop)

The improvements to the design are summarised below.

Floor coupling

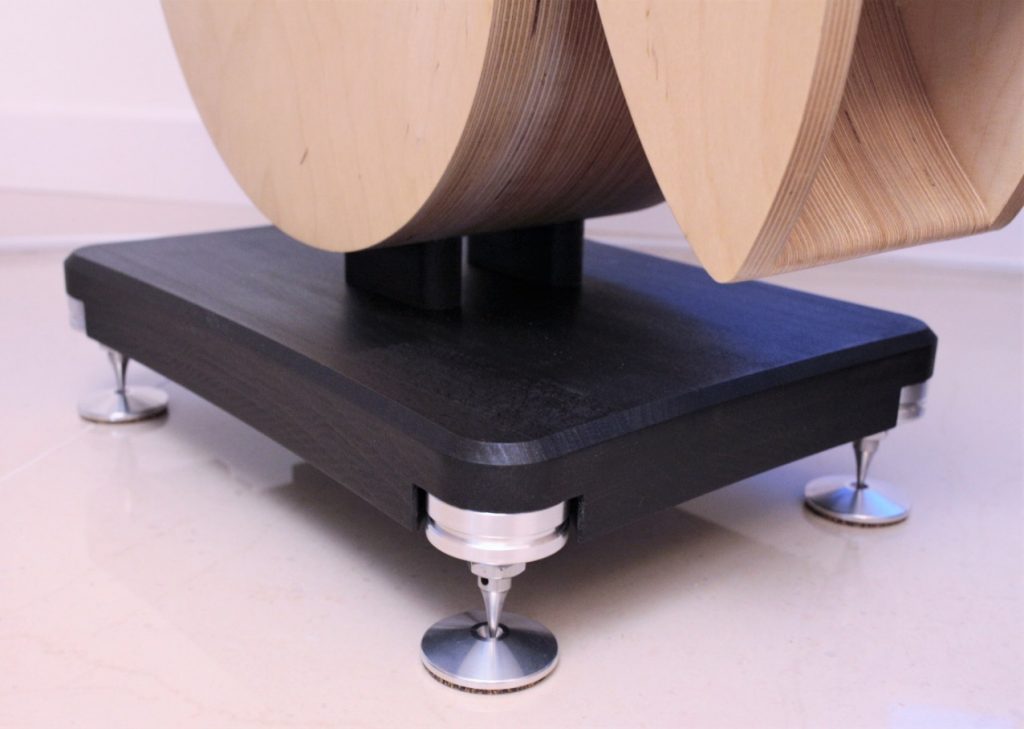

The slate plinth has been replaced with a 40 mm thick machined beech plinth that incorporates the equalization network and connection panel. The form of the curved cabinet is no longer interrupted by the cable connections. The plinth now comes pre-attached; it is only the spikes that need to be added. The plinth has been stained black ebony to highlight the curvature of the cabinet.

A bespoke M12 spike system has been designed, with large diameter spike shoes included for hard floors. The spike shoes are fitted with a cork based damping material for optimized floor interface. The profile of the spike has been designed to separate, rather than cut, fibres in carpet backing underlay backing. Spikes can be adjusted with a tommy bar and locked via the half-nuts. There is enough adjustment travel to allow axial optimization for a range of listening seat heights.

Connections, equalisation network and wiring

The network is now easily accessible via a composite access panel for bespoke tuning. The quality of the resistor was found to have a significant effect on sound quality and evolution through parallel Mundorf metal oxide types (in the mk 1) to Mundorf Supreme non-inductive wire wound type (in early versions of the mk 2) to a parallel thick film resistor array, has brought about improvements in transparency. Ring terminal tab connection / mounting enables solderless resistor changes to tailor sound quality to individual tastes and rooms. The combined effects of the resistor upgrade, BMR unit chassis reinforcing doubler and magnet brace render the capacitor redundant in the vast majority of set-ups. For listeners with relatively dull systems and rooms, or who want more air / sparkle, the capacitor (pre-installed) can be reconnected via solderless connections. The network can also be easily bypassed for systems that incorporate digital equalisation and room correction. Heavier gauge Gekko Cable is now used to connect the network to the drive unit

The polyurethane domed badges have been replaced with chemically etched enamel filled stainless steel badges produced by a company in Birmingham with 130 years experience. The badges are inlaid into the cabinet.

Drive unit

The BMR drive unit chassis is now structurally reinforced with a laser cut 3 mm stainless steel mount reinforcing element.

Effects on Sound Quality

The original slate based Curvi-BMR already achieves a remarkably high level of sound quality, as described by David Price in his StereoNet review. These seemingly minor design changes have led to improvements in stereo image quality and dynamics. The speaker scored highly in these aspects before, but improvements are nonetheless there to be heard. There is also more bass weight with improved texture. Treble and mid-range are now even more natural sounding.

Contact for more information:

CHRIS LIAUW

Designer of the Curvi speakers

chris.liauw.curvi.hifi@googlemail.com